Failure & Root Cause Analysis

IEC's metallurgical engineers understand that the profitability of your operation and the safety of your employees depends upon the reliability of the facilities and the equipment that you operate. However, we all know that on occasion components fail and mechanical equipment breaks down.

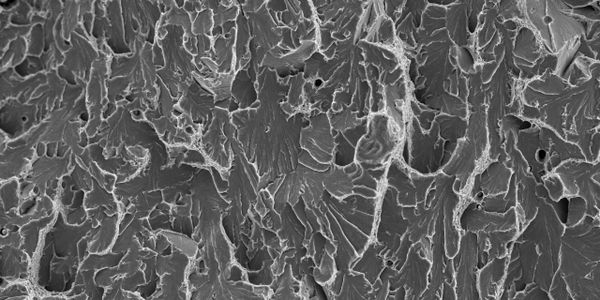

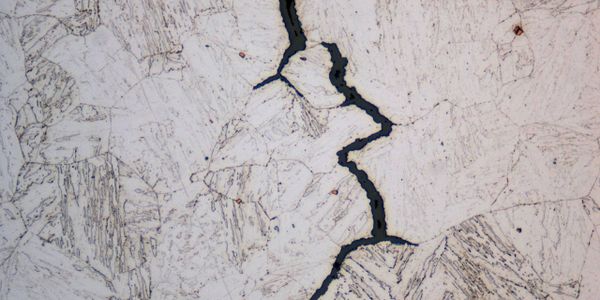

IEC has decades of experience providing failure and root cause analysis for the electric power generation, oil field, and process industries. Whether the failure is corrosion-related or mechanical in nature, we offer a complete range of laboratory analyses including: light optical and electron microscopy, hardness testing (both Rockwell and microhardness), compositional analyses, x-ray diffraction, and mechanical testing to assess and identify the damage mechanism. Effective failure analysis requires more than just the tools and the training on how to use them. More often than not, failures are the result of the specific application and operation of the materials – to properly identify these conditions, you need real-world experience. IEC’s engineers and analysts have worked in the oil and gas and electric utility industries, and they have practical manufacturing and design experience. They have been to the field and crawled through the plants and facilities performing failure analyses and equipment condition assessments. IEC's engineers are familiar with the capabilities of personnel at modern generating stations and they know what questions to ask in order to gather the information necessary to assess the operating conditions that may be contributing to the failure.

Identifying the damage mechanism may be only part of the investigation. While the root cause of some failures is immediately apparent, at other times sorting out the underlying cause requires a more complex analysis. IEC’s staff have been trained in conducting and have participated in numerous complex root cause analyses (RCAs). When, based upon identification of the mechanism, the cause of the failure is known or readily apparent, or the consequences of failure are minimal, it may not be justified to perform a rigorous RCA. However, when personnel safety is a consideration, or when the consequences of additional failures may result in considerable down time and expense, IEC is ready to assist you with a more formal RCA.

Copyright © 2024 Investigative Engineering Corporation - All Rights Reserved.

Powered by GoDaddy